Sand Viper® Piping System

Engineered for Extreme Abrasion—Built to Outlast Steel 9:1

The Sand Viper® Piping System by Bailey-Parks Urethane is designed for high-wear applications involving abrasive materials. Constructed from anti-static, high-performance 90A urethane, this system offers exceptional resilience and superior wear resistance, outperforming traditional steel piping by a 9:1 ratio.

Key Features

Durability

Outlasts traditional steel piping 9:1

Material

Anti-static 90A urethane

System Compatibility

Suitable for both pressure and vacuum-operated systems

Sizes Available

4″, 6″, and 8″ diameters in Schedule 80 standards

Customization

Fully customizable configurations using specialized urethane adhesives

Pressure Rating

Up to 50 PSI

Components

Our Sand Viper® components are manufactured with precision and care, ensuring each part meets the highest standards of quality and durability. From specialized pipe sections to custom fittings, every component is designed to work seamlessly together, creating a comprehensive solution for your most challenging material handling needs. Below, you’ll find detailed information about each key component in the Sand Viper® system.

All-Urethane Pipe

The All-Urethane Pipe stands as the cornerstone of the Sand Viper® Piping System. This innovative component showcases our commitment to durability and performance, featuring our signature anti-static 90A high-performance urethane construction. Engineered for the most demanding industrial applications, it delivers unmatched wear resistance and operational flexibility.

- Anti-static 90A high-performance urethane construction

- Industry-leading 9:1 wear resistance ratio compared to steel

- Pressure rated up to 50 PSI

- Lightweight and easy to handle

- Available in 4″, 6″, and 8″ diameters

- Standard 120″ lengths

- Compatible with all Sand Viper® components

- Sizes: Available in 4″, 6″, and 8″ diameters, each in standard 120″ lengths

Compression Hose Clamp

The Compression Hose Clamp delivers industrial-grade performance for demanding piping applications. This heavy-duty connector combines superior strength with practical functionality, offering a secure and reliable solution for high-wear environments. Engineered with premium materials and attention to detail, it’s the perfect complement to any professional piping system.

- Heavy-duty galvanized steel construction with integrated rubber liner

- Fast, secure, and leak-resistant connections

- Superior rust and corrosion resistance

- Reduces vibration

- 4″ diameter

- Professional-grade durability

- Quick installation and maintenance

- Sizes: Currently available in 4” diameter only

Lined Aluminum Pipe

The Lined Aluminum Pipe represents the perfect fusion of lightweight design and industrial resilience. This innovative component features a durable aluminum shell enhanced with our signature high-performance urethane lining, delivering exceptional wear resistance while maintaining easy maneuverability. Engineered for optimal performance in demanding environments, it sets a new standard for modern piping solutions.

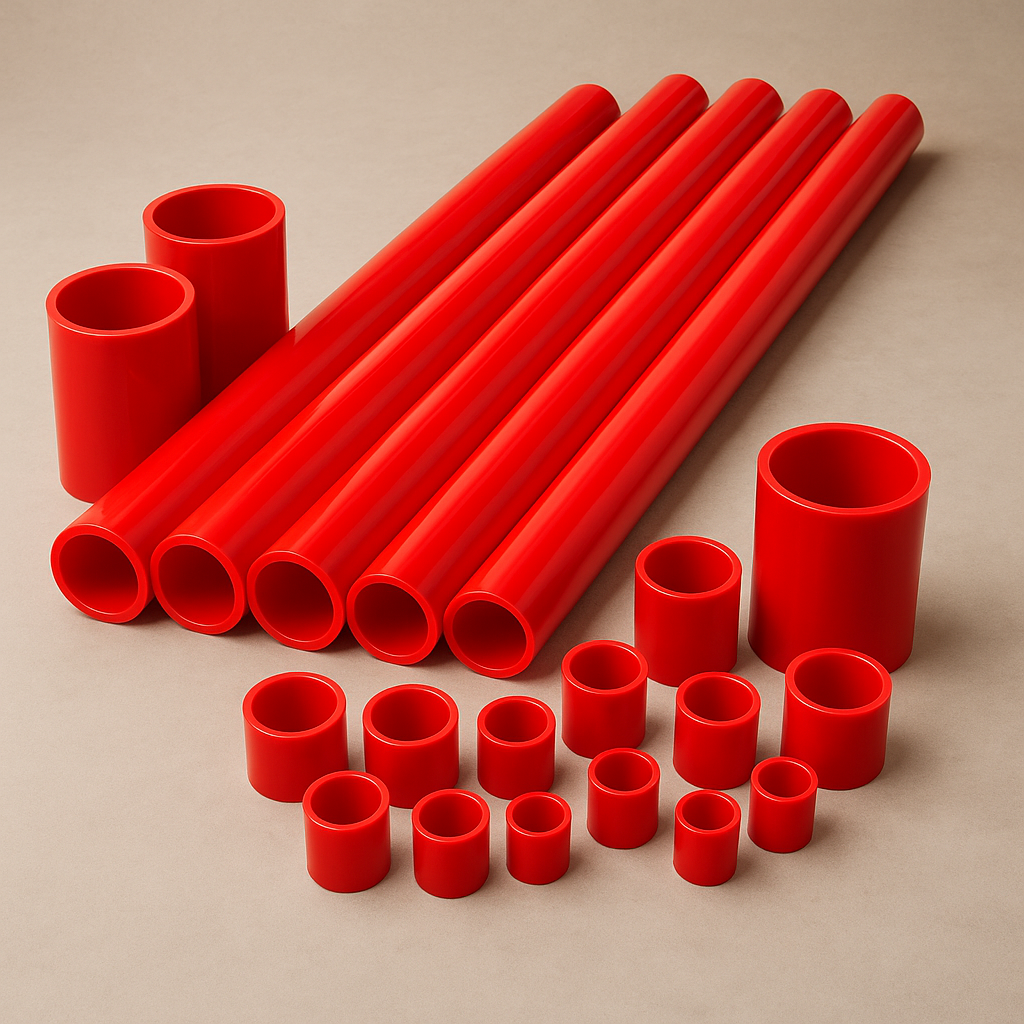

Couplers, Reducers, Flanges, and Caps

These essential connection components demonstrate our commitment to comprehensive system solutions. Fabricated with our signature anti-static high-performance urethane, these components deliver superior wear resistance and seamless integration. Engineered for maximum versatility and durability, they provide reliable connections across diverse industrial applications.

- Exceptional wear resistance and durability

- Withstands up to 50 PSI

- Compatible with Sand Viper 4″, 6″, and 8″ Schedule 80 piping

- Easy, field-ready installation with adhesive bonding

- Sizes: Available in standard Schedule 80 sizes

Lined Cam Locks and Hose End Connectors

Our Lined Cam Locks and Hose End Connectors exemplify cutting-edge connector technology. These essential components combine lightweight aluminum construction with our proprietary urethane lining, delivering unmatched durability and ease of use. Designed for seamless integration and long-term reliability, they represent the perfect connection solution for demanding industrial applications.

- Aluminum construction with high-performance 90A urethane lining

- 9:1 longevity advantage over traditional materials

- Quick-connect functionality

- Optimized weight reduction

- Superior wear resistance

- Maintenance-friendly design

- Professional-grade reliability

- Sizes: Currently available in 4″ size only

Modular Drop Tee

The Modular Drop Tee showcases advanced engineering for superior material handling. This robust component features a steel frame reinforced with our specialized urethane lining, creating an exceptionally durable solution for high-stress applications. Purpose-built for demanding industrial environments, it delivers outstanding performance and adaptability in bulk transport systems.

- Steel construction with high-performance 90A urethane lining

- Exceptional wear resistance in high-flow areas

- Versatile adapter compatibility

- Optimized for bulk transport applications

- High-velocity air system compatible

- Professional-grade durability

- Simple installation and maintenance

- Sizes: Available in 5″ and 6″ sizes

Elbows, Tees, 45° Laterals, 45° Wyes

Our comprehensive line of directional components showcases advanced engineering for optimal flow control. These precision-manufactured fittings feature strategically reinforced wear zones and versatile configurations, delivering exceptional performance in demanding industrial environments. Each component is optimized for maximum service life and system efficiency.

- Extra-thick wall design in high-wear sweep zones

- Built to handle abrasive media with maximum longevity

- Rated for up to 50 PSI in pressure or vacuum systems

- Fast, field-ready installation using urethane adhesives

- Configurations:

22.5° Elbows

45° Elbows

60° Elbows

90° Long Radius Elbows

90° Short Radius Elbows - Sizes: Available in 4″, 6″, and 8″ Schedule 80 sizes

Assembly Instructions

For step-by-step guidance on assembling the Sand Viper® Piping System using specialized urethane adhesives, please refer to our Urethane Adhesive Instructions.

Applications

The Sand Viper® Piping System is trusted across various industries for handling abrasive materials:

Glass Production Plants

Efficiently conveying abrasive glass particles

Fracking Operations

Reliable in both production and transport of fracking sand

Slurry Transport

Moving sand, slurry, and other abrasive mixes between facilities

Wood Processing

Transporting sawdust, wood chips, and shavings

Coal Slurry Systems

Designed for coal handling; ready for renewed demand

Construction

Conveying dry cement, concrete, and aggregates on-site

Blast Media Systems

Ideal for sandblasting equipment and OEM use

Sand & Gravel

Ideal for bulk handling in construction and infrastructure

Mining Operations

Used in pneumatic systems for ore, tailings, and abrasive bulk flow

Assembly Instructions

For step-by-step guidance on assembling the Sand Viper® Piping System using specialized urethane adhesives, please refer to our Urethane Adhesive Instructions.

Ready to Upgrade Your Industrial Piping?

Experience the superior performance and longevity of the Sand Viper® Piping System for yourself. Our expert team is ready to help you design a custom solution that meets your specific needs.