Urethane in the Grain Handling Industry

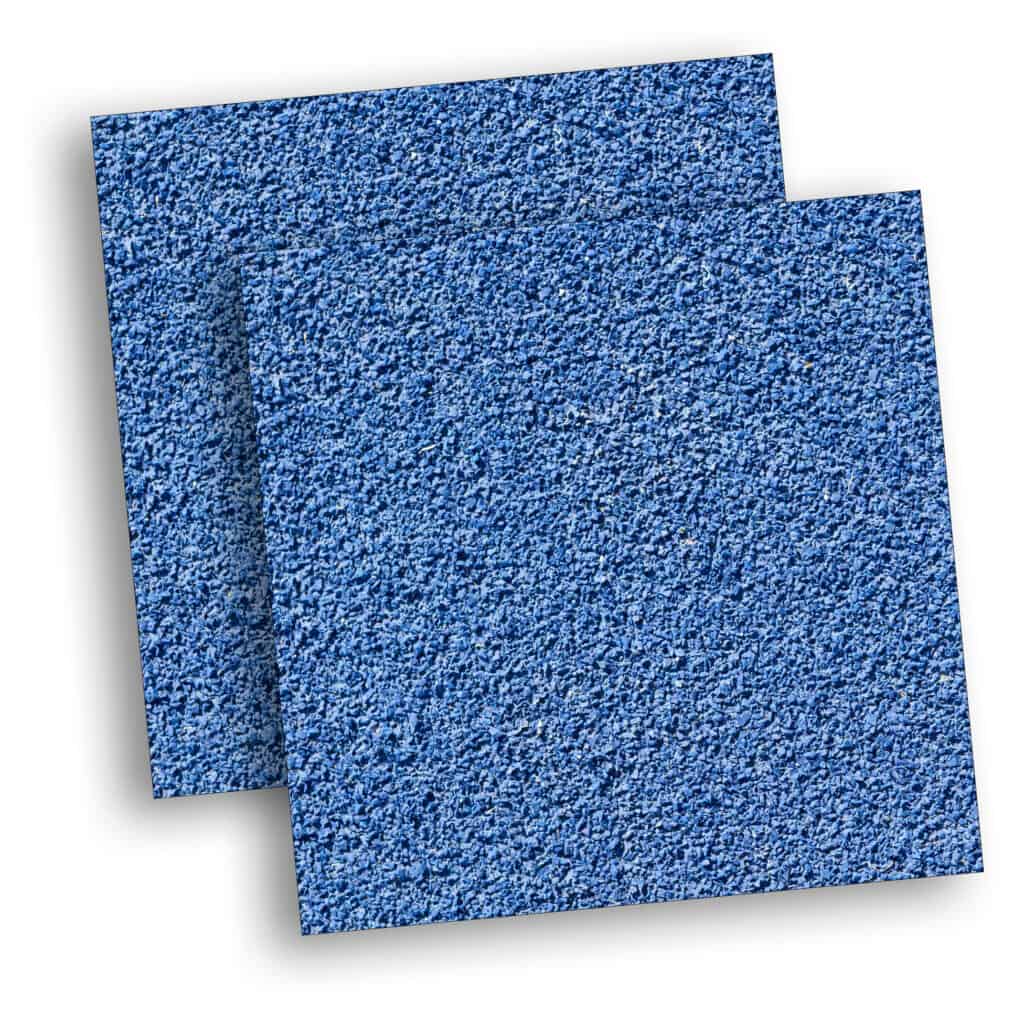

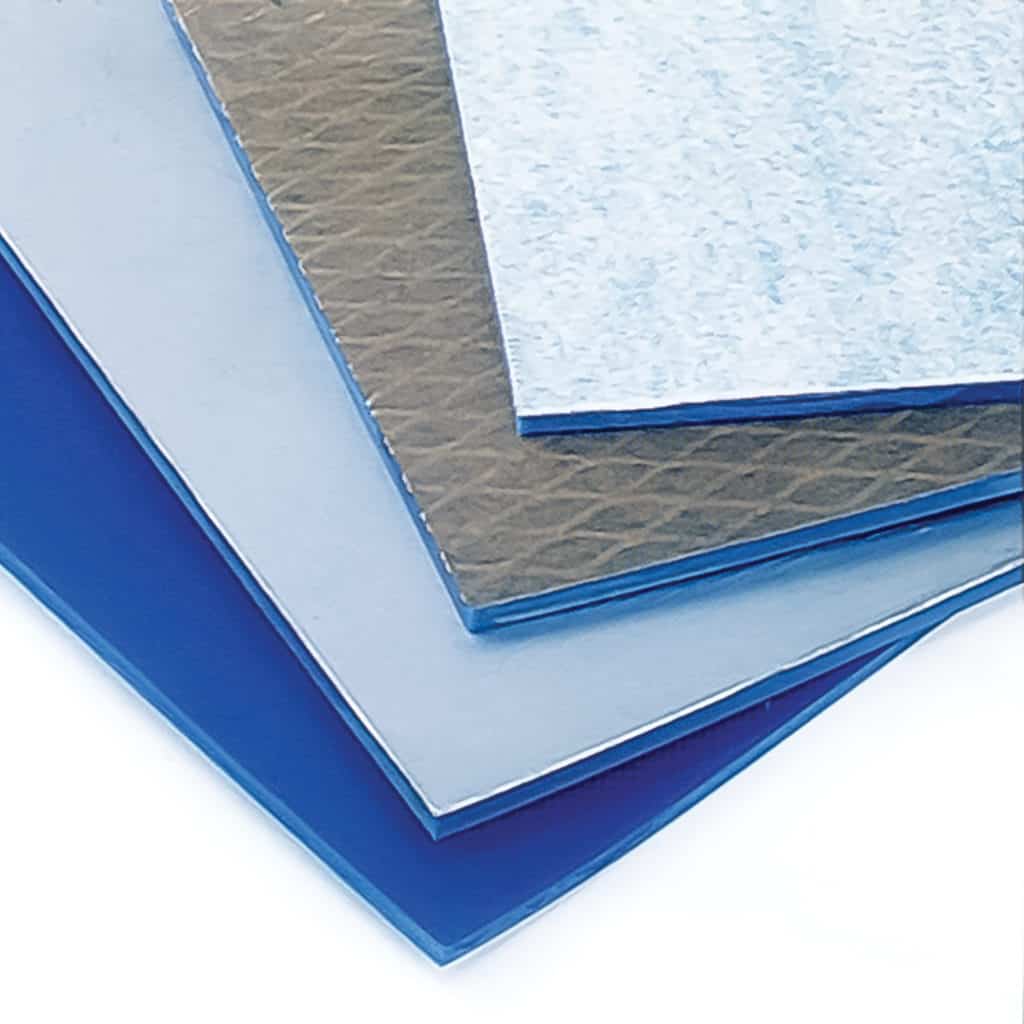

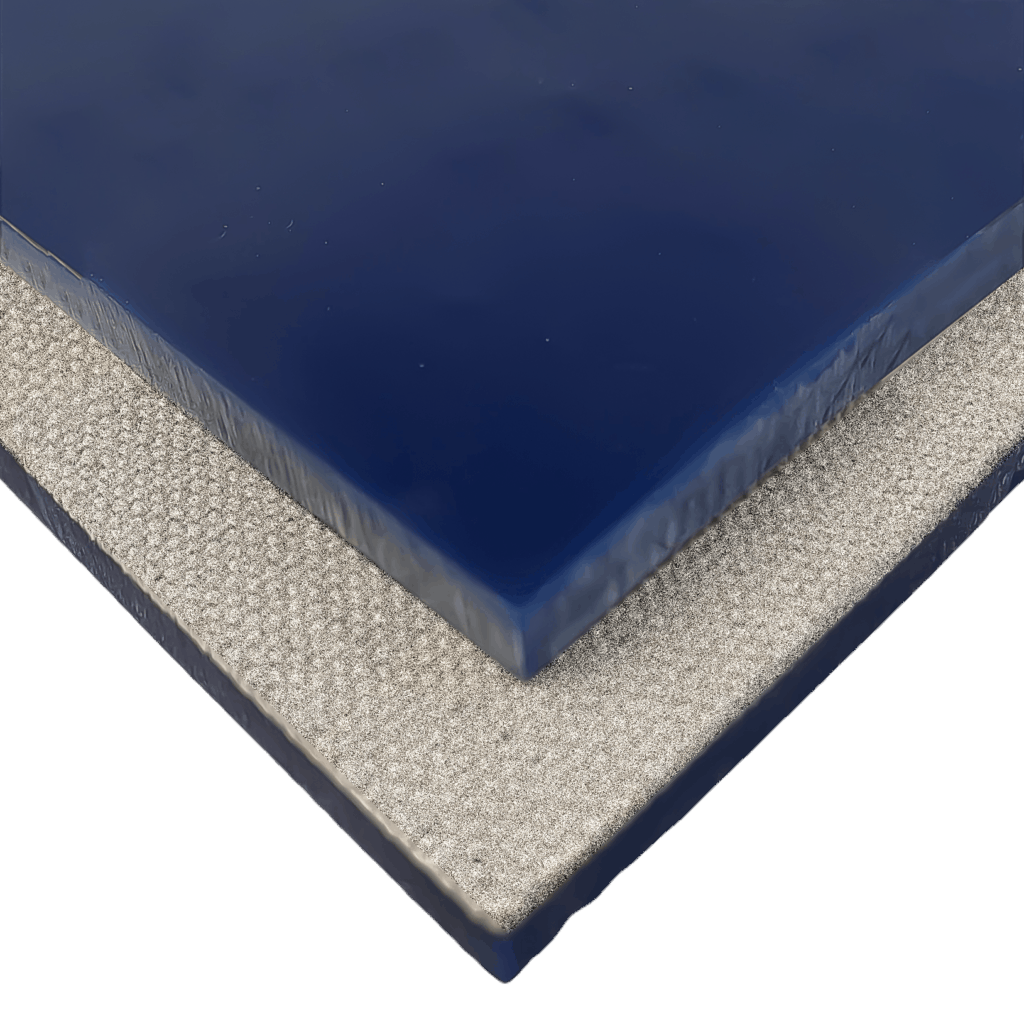

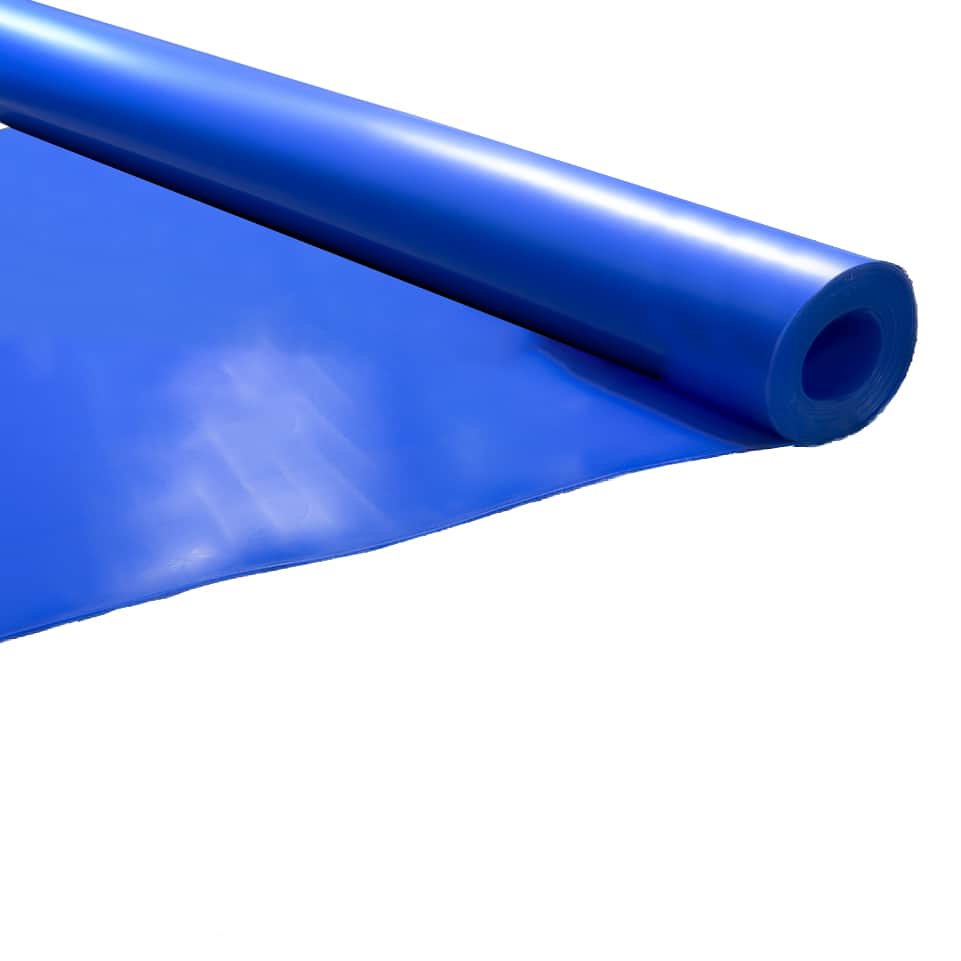

Diamondback® polyurethane sheets are among the most versatile of all lining materials. Our Diamondback® liners provide outstanding resistance to abrasion and wear problems. Our General Purpose Diamondback® sheets also meet FDA standards for dry food handling.

Diamondback® provides outstanding resistance to both impingement and frictional abrasion. It is relatively easy to fabricate and install and the cost is competitive with other abrasion resistant materials. Its softness cushions to protect grain, feed and other materials from breakage. And Diamondback® liners meet FDA standards for dry food handling.