Custom Mold Making Services

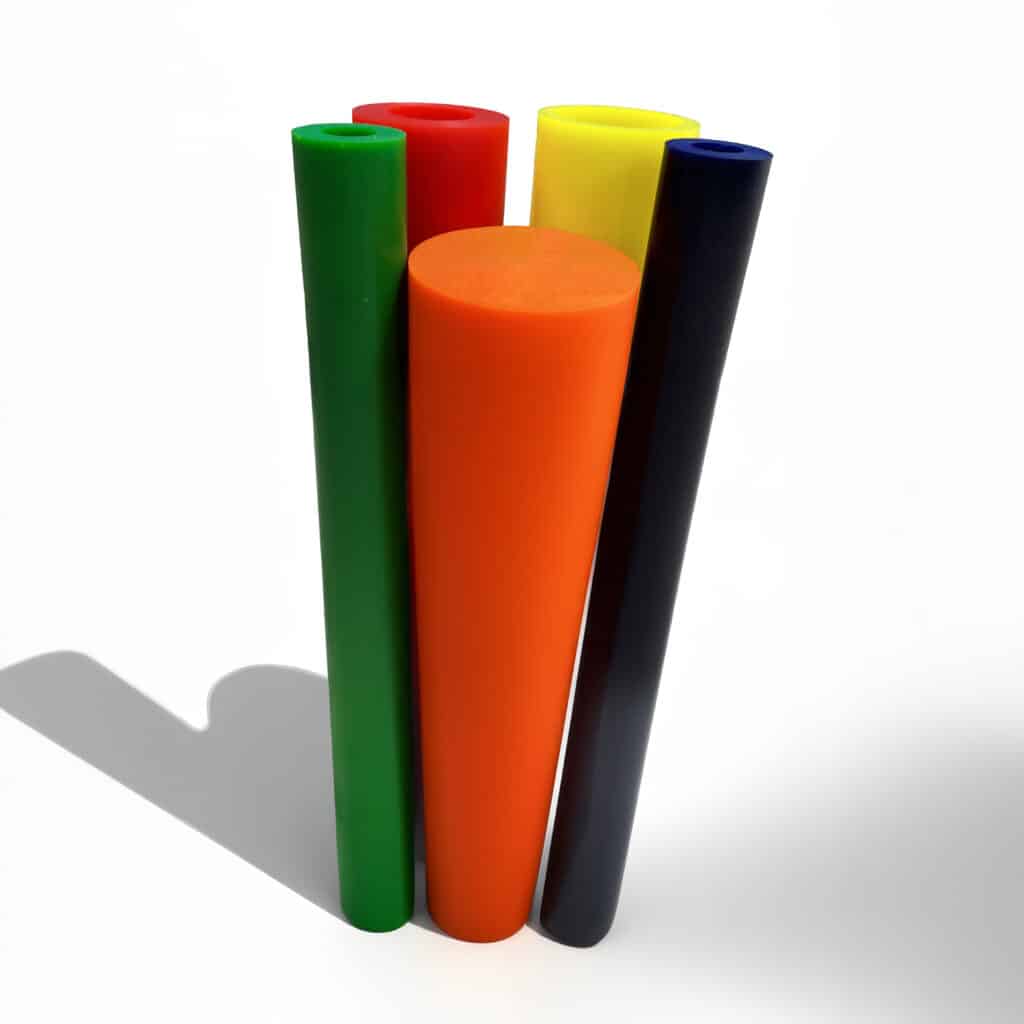

Bailey-Parks has been designing, engineering, producing and testing custom urethane molded products since 1970. With more than 600 different polyurethane molding compounds available, we can devise specific formulations of ethers, esters, MDIs, TDIs, TPUs, hardnesses and colors to meet your exact specifications.

Almost 100 percent of our tooling is done in-house, using steel, aluminum and/or composite materials. We can create plastic injection molds, compression molds and centrifugal casting molds, among others. The tooling department also supports the Bailey-Parks roller division by building roller cores and repairing damaged rollers prior to recovering.

Our fully staffed tool and mold-making department is located at our plant in Memphis, Tennessee. With design, engineering and manufacturing staff all under one roof, we provide turnkey solutions to meet your custom urethane molding needs.

Brief List of Custom Molded Urethane Products:

- Abrasive blasting masks to protect finished surfaces

- Cable protectors for roadways

- Classifier shoes (e.g., flight shoes, fan screws, de-watering screws)

- Hydrocyclones

- Large and small vibratory bowls

- Pipe Linings

- Machine mounting pads

- Testing seals for both hydraulic or pneumatic applications

- Torsion and compression springs

- Bumpers

- Bushings

- OEM Molded Urethane Products

- Compression Molded Parts

- Open Cast Molding

- Belt Scrapers

- Molded Ceramic Bead and Chip Parts