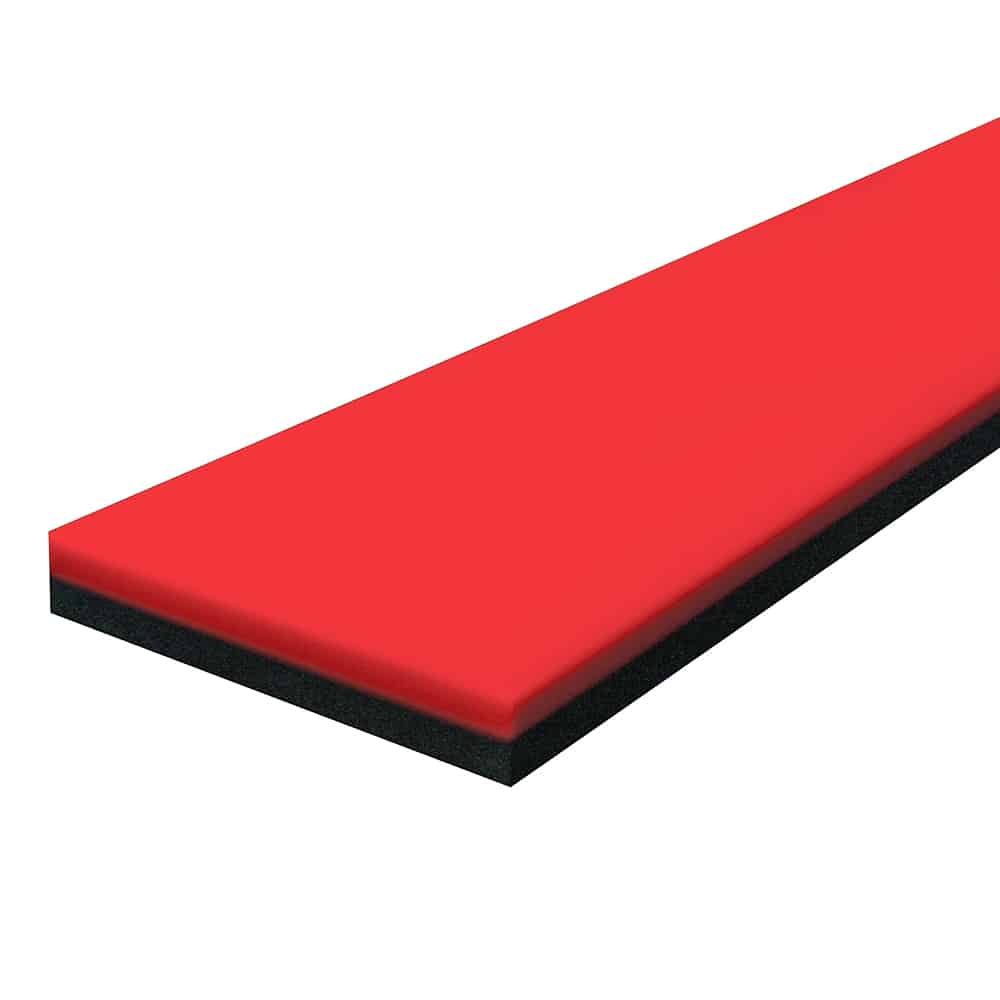

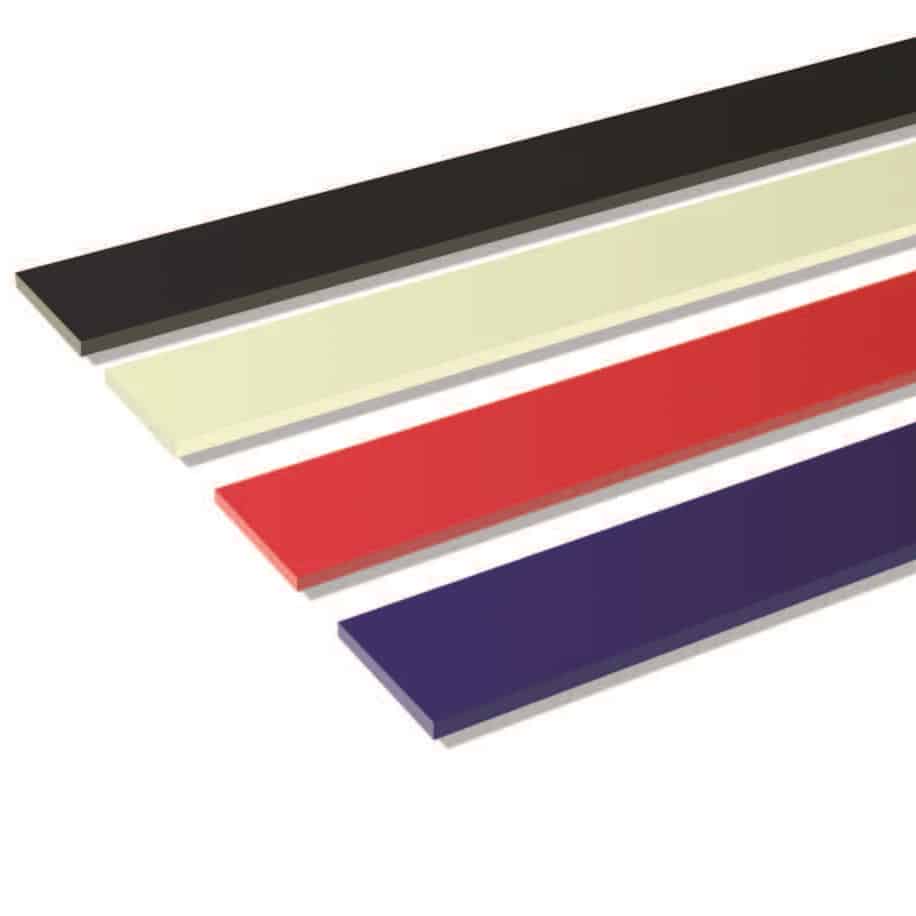

Diamondback® Belt Wiper Tri-Layer

Having a TRI-LAYER BELT WIPER on your system allows for the removal of hard and solid debris. The soft durometer in the center provides the wiping effect necessary to clean non-solids and moist products. The last layer, which is the same in rigidity as the first layer, allows the blade to maintain its form without bending. This reduces the vibratory drag and belt chatter of the soft middle layer. As a bonus, the wiper can be rotated to get double the life.